MÁY TẠO KHÍ NITƠ (N2), OXYMAT - ĐAN MẠCH

- Máy tạo khí Ni tơ (N2), Oxymat của Đan Mạch

- Model: N4500 ECOx3

- Độ thuần khí Ni tơ từ 5%(95) lên đến 99,9999%

- Lưu lượng từ 27,000 m3/giờ đến 180 m3/giờ

- Áp suất đầu vào: 5-7 kgf/cm2

- Sử dụng hạt CMS (Carbon Molecular Sieve), thời gian sử dụng lên đến 40,000 giờ hoạt động.

- Điện áp nguồn: 230 V / 1phase / 50Hz

Our Nitrogen Product range covers 18 standard models with capacity in the range from 0,27 to 5.400 m3/hour. Flow meassured in Sm3/h. Purity up to 99,9999% ..

X-versions 3 to 6 are supplied as framebuilt solutions, buffer vessels, filters, Advanced control, dewpoint, pressure, temperature, flow, purity and remote monitoring included.

STANDARD MODEL | Độ thuần khí Ni tơ (N2) / Purity |

5 %

95 | 3 %

97 | 2 %

98 | 1 %

99 | 0.5 %

99.5 | 0.1 %

99.9 | 500 ppm

99.95 | 100 ppm

99.99 | 50 ppm

99.995 | 10 ppm

99.999 | 5 ppm

99.9995 | 1 ppm

99.9999 |

N040 ECO | N2 Sm3/Hour | 5.00 | 4.00 | 3.50 | 3.00 | 2.49 | 1.67 | 1.38 | 0.78 | 0.62 | 0.44 | 0.39 | 0.27 |

N075 ECO | N2 Sm3/Hour | 14.00 | 11.00 | 9.00 | 7.00 | 6.40 | 4.30 | 3.54 | 2.00 | 1.61 | 1.12 | 1.00 | 0.70 |

N150 ECO | N2 Sm3/Hour | 27.00 | 24.00 | 20.00 | 16.00 | 13.51 | 9.08 | 7.47 | 4.22 | 3.39 | 2.36 | 2.11 | 1.49 |

N225 ECO | N2 Sm3/Hour | 40.00 | 35.00 | 30.00 | 25.00 | 20.62 | 13.86 | 11.41 | 6.44 | 5.17 | 3.61 | 3.22 | 2.27 |

N350 ECO | N2 Sm3/Hour | 60.00 | 50.00 | 45.00 | 35.00 | 32.00 | 21.50 | 17.70 | 10.00 | 8.03 | 5.60 | 5.00 | 3.52 |

N600 ECO | N2 Sm3/Hour | 90.00 | 80.00 | 70.00 | 55.00 | 45.51 | 30.58 | 25.17 | 14.22 | 11.42 | 7.96 | 7.11 | 5.01 |

N800 ECO | N2 Sm3/Hour | 135.00 | 120.00 | 100.00 | 75.00 | 63.00 | 45.00 | 39.00 | 19.80 | 17.70 | 13.00 | 10.80 | 7.86 |

N1000 ECO | N2 Sm3/Hour | 225.00 | 200.00 | 160.00 | 130.00 | 101.24 | 72.31 | 62.67 | 31.82 | 28.44 | 20.89 | 17.36 | 12.63 |

N1850 ECO | N2 Sm3/Hour | 315.00 | 270.00 | 230.00 | 180.00 | 121.96 | 90.96 | 77.49 | 43.79 | 39.07 | 31.96 | 30.19 | 21.31 |

N2650 ECO | N2 Sm3/Hour | 450.00 | 400.00 | 330.00 | 280.00 | 197.15 | 147.03 | 125.27 | 70.79 | 63.15 | 51.67 | 48.80 | 34.45 |

N3150 ECO | N2 Sm3/Hour | 675.00 | 575.00 | 450.00 | 400.00 | 267.43 | 199.45 | 169.93 | 96.02 | 85.67 | 70.09 | 66.20 | 46.73 |

N4500 ECO | N2 Sm3/Hour | 900.00 | 770.00 | 650.00 | 500.00 | 343.40 | 256.10 | 218.20 | 123.30 | 110.00 | 90.00 | 85.00 | 60.00 |

N3150 ECOx2 | N2 Sm3/Hour | 1350.00 | 1150.00 | 900.00 | 800.00 | 534.87 | 398.89 | 339.86 | 192.05 | 171.33 | 140.18 | 132.39 | 93.45 |

N4500 ECOx2 | N2 Sm3/Hour | 1800.00 | 1540.00 | 1300.00 | 1000.00 | 686.80 | 512.20 | 436.40 | 246.60 | 220.00 | 180.00 | 170.00 | 120.00 |

N4500 ECOx3 | N2 Sm3/Hour | 2700.00 | 2310.00 | 1950.00 | 1500.00 | 1030.20 | 768.30 | 654.60 | 369.90 | 330.00 | 270.00 | 255.00 | 180.00 |

N4500 ECOx4 | N2 Sm3/Hour | 3600.00 | 3080.00 | 2600.00 | 2000.00 | 1373.60 | 1024.40 | 872.80 | 493.20 | 440.00 | 360.00 | 340.00 | 240.00 |

N4500 ECOx5 | N2 Sm3/Hour | 4500.00 | 3850.00 | 3250.00 | 2500.00 | 1717.00 | 1280.50 | 1091.00 | 616.50 | 550.00 | 450.00 | 425.00 | 300.00 |

Conversation rates for nitrogen: Sm3 = 1.15 kg, 1 Nm3 = 1.25 kg; 1 kg = 0.87 Sm3 & 0.80 Nm3

1 Sm3 = 0.92 Nm2

1 Nm3 = 1.09 Sm3

Notes:

*1 – Stated flow in Sm³/hour are for operation with reference to 15°C, 981 mbar. Inlet pressure 7 barG. Flow variance ±5%

*2 – Stated air consumtions in FAD m³/min are for operation with reference to 20°C, 1 barA, -acc. to ISO1217c

*3 – Capacity of the plant is stated at 30°C ambient air temperature. Variance±5%

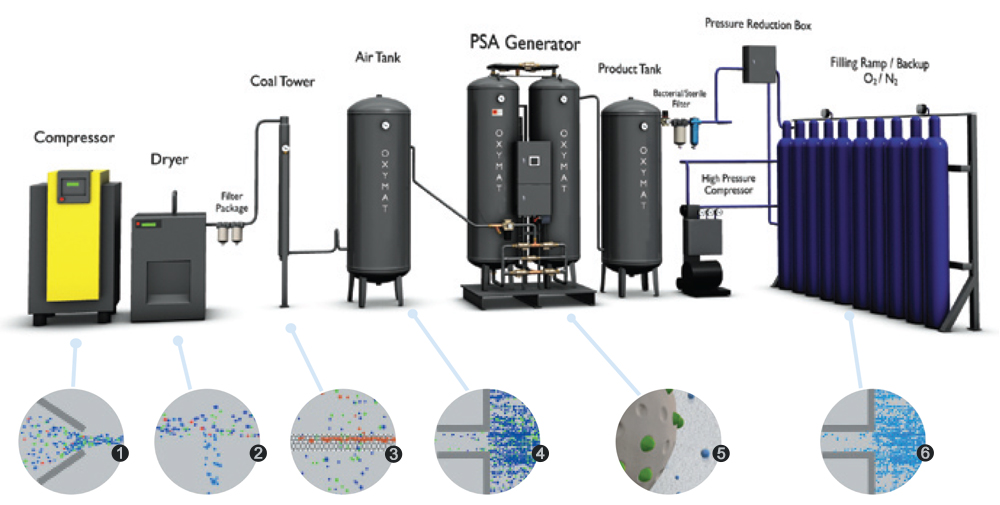

3D Scheme

The PSA process is an extremely clean operation and the only ‘raw material’ is ‘air’. On-site generators allow for an uninterrupted supply of gas with a high purity output. This means that you can produce gas where and when you need it, and in the exact quantity and quality you need.

1. Compressor

increases air to required level of pressure

2. Dryer

removes moisture from air (air humidity) by cooling

3. Coal tower

adsorbs harmful organic impurities such as oil vapours and hydrocarbon compounds

4. Air tank

accumulates necessary volume of air for PSA generator

5. CMS

filling with its ion- exchange bed traps oxygen molecules and allows nitrogen molecules to stream through

6. High Purity Oxygen

flows from PSA generator to product tank and is ready for use

Nitrogen Generator System

How it works

• At Oxymat, we use two columns with molecular sieves to ensure continuous production.

• Dry compressed air is blown through a valve to the vessel where the pressure is built to reach 5 to 7 bar(g). Nitrogen is tied to a molecular sieve during the building of pressure, and the oxygen is allowed to pass through to the accumulation tank.

• While pressure is build in one vessel, the second remains without pressure.

• A part of the produced gas is used for regeneration of the molecular sieve.

• For Nitrogen a Carbon Molecular Sieve (CMS) is used. The molecular sieve is fully regenerative and has a life span on to 40.000 operation hours.

The entire PSA system can be subdivided into:

• Compressed air system (Air compressor, Refrigeration dryer, Air receiver & Filters)

• PSA skid

• Nitrogen receiver

• Nitrogen boosting & Filling Station (optional)

Optional supplies:

• Panel Display with electro galvanized sensor

• Touch Screen with zirconium sensor

• GSM modem for touch Screen

• Medical upgrade kit (Coalescing tower and bacterial filtration)